Maximizing Wastewater Resources

Preparing for Growth

Our Water Reclamation Facility sits on River Ave near the banks of Lake Macatawa. Because of its location, this wastewater treatment plant is limited in physical space for future expansion. To care for the resources we have and extend the life of our current wastewater infrastructure without requiring additional investments, we pay close attention to the capacity of our wastewater facility.

Due to their size and scope of work, commercial and industrial businesses utilize the majority of our capacity to treat wastewater. Because of the potential for exponential growth in business sectors, Holland BPW works to protect our limited resources and ensure that our capacity to treat wastewater remains available for all customers even as our community grows.

Monitoring Capacity

Because of our limited facility space, we ensure that no single industry sector uses more than 10% of our ability to treat all of our commercial & industrial customers. This means that we work carefully with our commercial & industrial customers to install pretreatment processes prior to discharging to our system. With pretreatment, this wastewater requires less demand on our wastewater systems, reducing the burden on our resources, and keeping rates fair for other ratepayers.

We monitor some industrial customers’ waste for concentrations of predetermined pollutants based on their industry and discharge. Our teams pay special attention to the pollutants that require more Holland BPW resources to treat such as grease, phosphorus, etc. Then we charge customers according to the demand that they place on our system above a determined threshold, encouraging them to pretreat their waste and avoid such charges in the process.

Protecting Our Investments

We work with businesses from the moment they have a physical presence in our community, and as they grow and need additional capacity, we encourage companies to install on-site pretreatment processes for their wastewater before they discharge it to our system.

Paying careful attention to who uses our facility’s capacity and how protects our investments in infrastructure from being utilized by only one industry or one company. That way, in the case that an industry might move away or close down in our service area, our assets and the investments of the community are not stranded or significantly reduced.

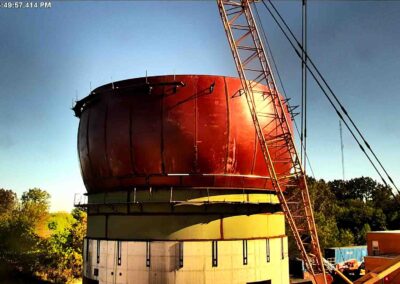

Reducing Biosolids

The anaerobic digester is another critical part of keeping our footprint small, reducing the amount of solid waste that we produce and increasing the quality of the solid waste leaving our facility. As a sort of mechanical gut, the anaerobic digester utilizes bacteria who break down biosolids while producing biogases.

Currently, we reduce the amount of liquid in our solid waste as much as possible and then pay to dispose of it at nearby landfills or as an additive to farm fields that grow crops not meant for human consumption. While this strategy has served us well, selling to landfills leaves us vulnerable to landfill price increases. What’s more, landfills have begun reducing the amount of solid waste that they will accept. With recycling on the rise, landfills receive less solid trash. Adding the same amount of biosolids to a reduced amount of solid trash could upset the balance of a landfill.

End Products of a Digester

An anaerobic digester not only reduces the amount of biosolids overall, but it treats them to a higher level. This will allow our end waste product a broader range of uses, such as fertilizer for crops fit for human consumption or even commercial lawn treatment, more commonly sold as milorganite.

In addition to the solids, we also have opportunities to utilize the biogas produced by the anaerobic microbes. This gas will help generate electricity to power the digester itself as well as meet some of the electricity needs of our Water Reclamation Facility. Likewise, the heat generated from these natural processes will help heat the tank itself in the winter along with two of our site buildings.