Celebrating Innovation

Reimagining Disinfection

Holland BPW’s Water Reclamation Facility (WRF) sits near the heart of downtown Holland. Bound by the city itself, Lake Macatawa, and neighboring wetlands, this facility has physical land restraints that our other plants do not. Overcoming this challenge requires innovative creative thinking.

In the past few years, we have added the anaerobic digester to our process to reduce solid waste outputs and maximize our treatment capacity. Now, we are looking to improve the final step in treating wastewater: disinfection.

Ultraviolet Light

Holland BPW currently adds a small amount of sodium hypochlorite to the water treated at the WRF as a disinfectant prior to discharge. The disinfection process kills or inactivates pathogens remaining in the water after the main treatment process, making it safe for discharge to Lake Macatawa.

This process is safe and effective, but recent advancements to ultraviolet technology and supply chain concerns pushed us to consider alternatives to our current process. After performing studies, learning more about ultraviolet (UV) technology and how other utilities utilized it, we determined that ultraviolet light was the best choice for disinfecting our treated water moving forward.

Benefits of Switching

UV disinfection works to inactivate harmful bacteria and other germs through intense light that damages their DNA, preventing them from replicating. It is unique in its ability to disinfect surfaces and water without using chemicals. This technology will allow us to save costs, reduce dependence on chemical suppliers and reduce chemicals added to treated water that is returned to nature.

The price of sodium hypochlorite can vary widely depending on world circumstances. As we found during the pandemic, disinfecting chemicals can become expensive and harder to source depending on current events. UV disinfection requires only power for lights. Switching to UV allows us to improve efficiency and reliability, ultimately benefiting our customers.

Additionally, UV disinfection is inherently safer for our workers and the ecosystem at large. Handling chemicals can be dangerous and requires additional precautions and procedures to keep our workers safe. Reducing the amount of chemicals stored at our wastewater treatment facility is also environmentally responsible as the risk of a spill is reduced.

Construction

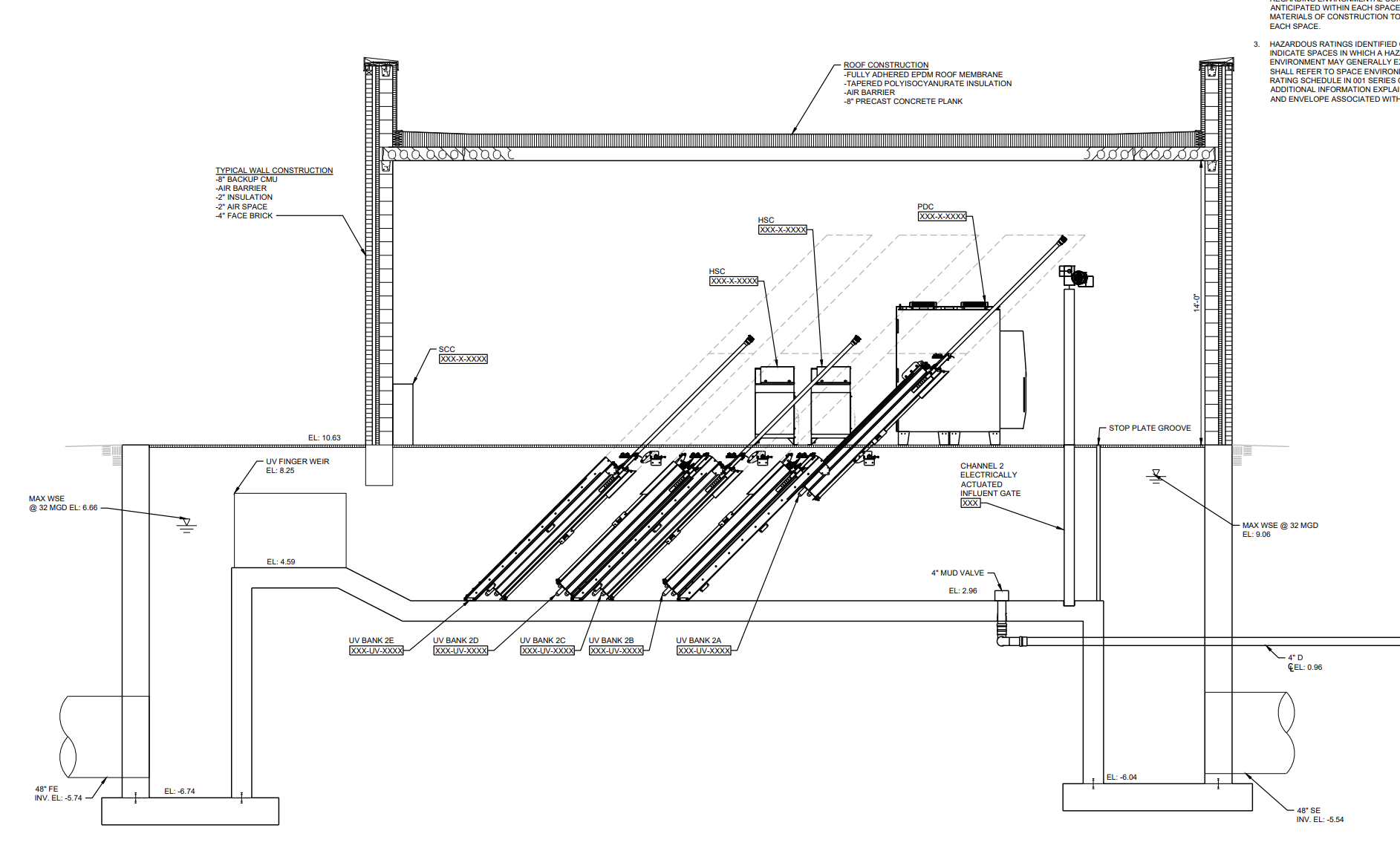

This project will include adding a small building to the footprint of the WRF. In this building, banks of UV lights will be submerged at an angle into the water. As the water passes through, the light disinfects it before it flows out to Lake Macatawa.

The project is designed with future growth in mind. There will be extra room in the treatment channels for possible future expansion as our community and wastewater treatment needs grow.

Project construction is expected to begin in 2026. We look forward to implementing this innovative project that creates resilient and efficient systems for our wastewater utility.