2020 Update:

Wastewater

Wastewater

Anaerobic Digester Project Awarded CWSRF Funding and Green Project Reserve Principle Forgiveness

Wastewater

Holland BPW Pursues ENVISION Certification for Anaerobic Digester

Wastewater

Sanitary Sewer Renewal in Areas Affected by High Lake Levels

Anaerobic Digester Project Awarded CWSRF Funding and Green Project Reserve Principle Forgiveness

Holland Board of Public Works completed the design and recently began construction on a 2 million gallon anaerobic digester. When complete, the digester will stand approximately 110 feet tall on the grounds of the Water Reclamation Facility (WRF). The project provides a solution to difficulties and rising costs the WRF faces regarding disposal of the plant’s biosolids. “Our goals are to address this challenge by investing in improvements that will support the community’s needs far into the future in a sustainable way that offers a positive return on investment” (Theo VanAken, Water Reclamation Facility Superintendent, 2019).

“Our goals are to address this challenge by investing in improvements that will support the community’s needs far into the future in a sustainable way that offers a positive return on investment”

– Theo VanAken, Water Reclamation Facility Superintendent

Anaerobic digestion is a sustainable process that uses microorganisms in absence of oxygen to break down solid waste. The new process is expected to reduce the volume of the WRF’s solid waste by 50%. This in turn will greatly reduce associated disposal costs and decrease the number of trucks necessary to transport solids to their end use. The reduced trucking also greatly reduces associated emissions, supporting the decarbonization goals of Holland’s Community Energy Plan.

The byproducts of HBPW’s anaerobic digestion process include biogas and Class A biosolids. The biogas will be captured and beneficially used to generate renewable heat and power that will offset electric and natural gas energy consumption at the WRF. Treating the solids to Class A biosolids provides a wide variety of beneficial reuse options including as a fertilizer, soil amendment, compost component or fill. By stabilizing solids through the digestion process, the project is also expected to further reduce odors at the site beyond the levels maintained by the WRF’s existing odor control system.

Holland Board of Public Works was awarded financing for the $33.7M project through the Clean Water State Revolving Fund (CWSRF) administered by the Michigan Department of Environment, Great Lakes and Energy (EGLE). CWSRF funding is a low interest (2%) loan program that assists qualified municipalities with the construction of needed water pollution control facilities. HBPW is financing the project via a $30M loan provided through the CWSRF program and $3.7M from the utility’s equipment replacement fund. Due to the highly sustainable nature of the anaerobic digestion process, HBPW will also receive $6M in principle forgiveness from the CWSRF’s Green Project Reserve (GPR), which will reduce the amount borrowed to $24M. The purpose of the Green Project Reserve is to encourage local municipalities to build sustainable infrastructure. Aspects of HBPW’s anaerobic digester project that led to the award include the anaerobic digestion process’ production of Class A biosolids and the utilization of biogas for heat and power generation.

Once the GPR principle forgiveness was approved, all of the program requirements needed to be completed within twelve months in order to receive the funds. Holland Board of Public Works pushed through in a challenging year marked by COVID-19 to complete the milestones on time. Knowing that a possible $6M award was on the high end, HBPW did not want to risk a reduction in funding. “COVID-19 slowed down our progress, but the project team really pulled together in getting everything completed on time. We are thankful we did, because the amount available through GPR funds for 2021 turned out to be much lower than what was awarded in 2020,” said Jane Monroe, Planning Engineer Manager.

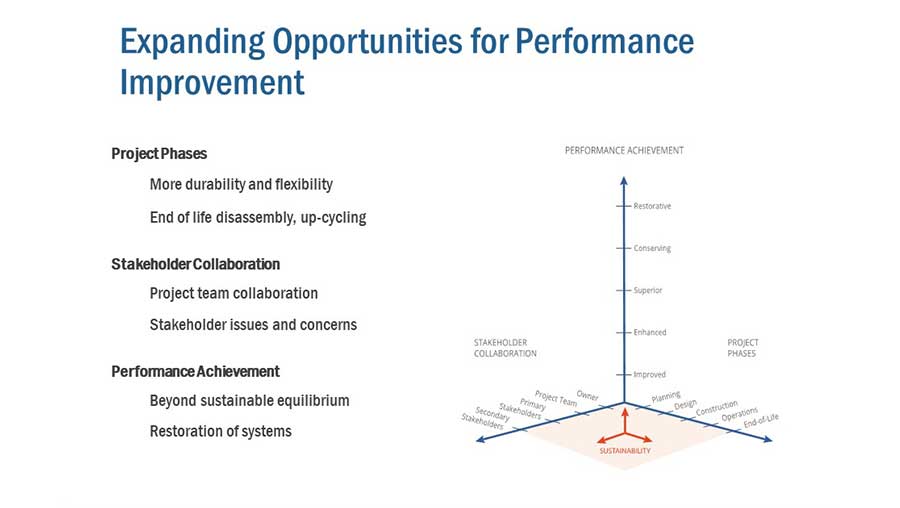

Due to the highly sustainable nature of the project, HBPW also applied the Institute for Sustainable Infrastructure’s (ISI) Envision™ framework to the project early in the project planning and throughout its design. Implementation of the framework’s sustainable principles will continue through the project’s construction and operation of the completed process in pursuit of Envision™ certification. Construction of the anaerobic digester project began in October 2020 and will take 34 months to build.

Holland BPW Pursues ENVISION Certification for Anaerobic Digester

Holland Board of Public Works received Platinum ENVISION recognition for Holland Energy Park in 2016. It was the first facility of its kind to receive the prestigious award. Now HBPW is pursuing ENVISION for the anaerobic digester project.

“The purpose of Envision is to foster a dramatic and necessary improvement in the performance and resiliency of our physical infrastructure across the full spectrum of sustainability”

– Sustainability and the Role of Envision, 2019

ENVISION is a sustainability framework for all types of infrastructure, administered by the Institute for Sustainable Infrastructure (ISI). “The purpose of Envision is to foster a dramatic and necessary improvement in the performance and resiliency of our physical infrastructure across the full spectrum of sustainability” (Sustainability and the Role of Envision, 2019). “As a guidance tool, Envision provides industry-wide sustainability metrics for all infrastructure types.”

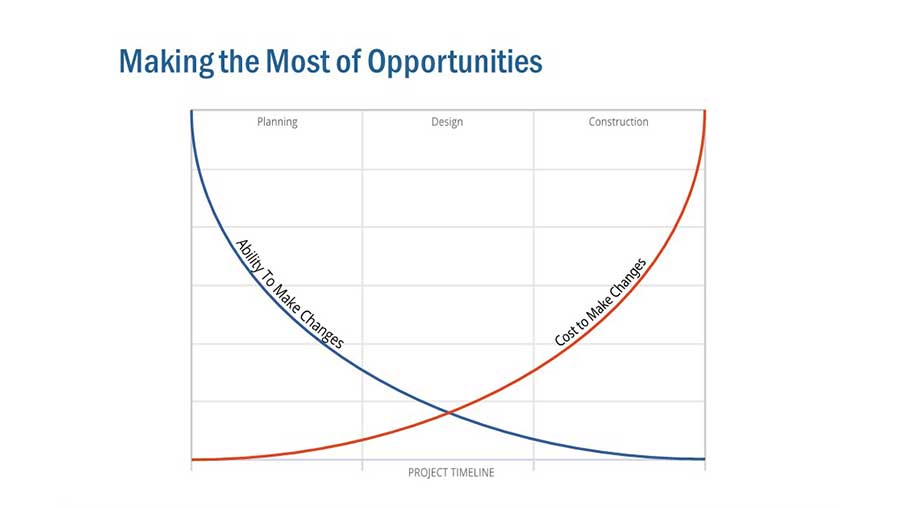

The ENVISION certification process is designed to implement best practices for sustainability early in the planning phase of a project. Choosing to build sustainable infrastructure from the start is much easier and more cost effective than making changes later in the game. “Before you are too far into the planning and design of a project, ENVISION’s pre-assessment checklist and guidance manual help you consider how sustainability can be incorporated into all phases of the project,” explained Sam Bender, Water & Wastewater Process Engineer.

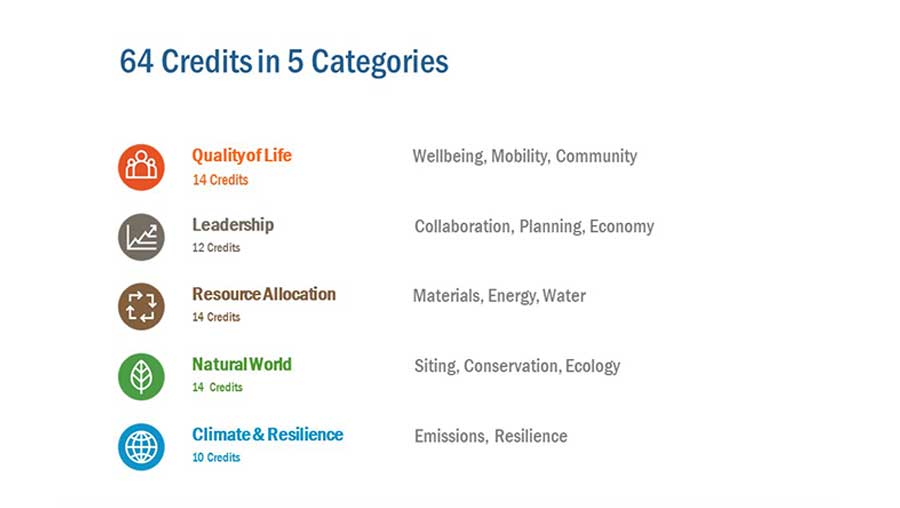

Holland Board of Public Works is pursuing Gold Level ENVISION certification for the anaerobic digester project. “Our objective is to achieve ENVISION without adding additional costs to the project,” said Jane Monroe, Planning Engineer Manager. HBPW’s planning and design process fundamentally includes many of the practices that ENVISION uses as criteria for certification. ENVISION scores are calculated by level of achievement earned within 64 credits in five categories: Quality of Life, Leadership, Resource Allocation, Natural World, and Climate & Resilience.

Stakeholder engagement is a common practice for Holland Board of Public Works that aligns with ENVISION’s leadership category. Regarding the anaerobic digester, HBPW collaborated with a number of interested departments within the City of Holland and local environmental organizations: Community & Neighborhood Services, Transportation, Parks & Recreation, Downtown Development Authority (DDA), Planning Commission, City Council, the Macatawa Area Coordinating Council (MACC), and Outdoor Discovery Center (ODC). “Stakeholder engagement does not add cost to the project, but allows us to listen to valuable feedback and develop synergies within our community,” said Bender. “For example, Holland’s Parks and Recreation Department is interested in utilizing Class A biosolids as a compost amendment for leaf collection.”

ENVISION considers the full life cycle of the infrastructure, so the certification does not expire. Having third-party verification shows that Holland Board of Public Works is making sustainable choices that will have beneficial long-term effects. The anaerobic digester a good example of sustainable infrastructure because it will make a positive impact in a variety of areas. The anaerobic digester will reduce the amount of solid waste produced at the Water Reclamation Facility (WRF). Less waste results in fewer trucks and associated emissions, advancing the Community Energy Plan goal of less than 10 metric tons of carbon per person. Additionally, the byproducts of the new process will be used for beneficial reuse. High quality Class A biosolids will be used as sustainable fertilizer and the biogas produced from destruction of solids in the digester will be utilized for generating renewable electricity and heat that will be used at the WRF. Quality of life for the community will also be improved with less odors coming from the WRF.

HBPW’s anaerobic digester project has already garnered recognition for being sustainable. Plans for the digester helped earn HBPW a Premier Utility Management Performance (PUMP) Award from the Michigan Water Environment Association (MWEA) in partnership with the Michigan Department of Environment, Great Lakes, and Energy (EGLE). Criteria for the PUMP Award rank among the national industry’s highest standards and require aptitudes in at least two of ten Effective Utility Management (EUM) attributes. HBPW’s Holland Area Water Reclamation Facility was recognized for excellence in nine EUM areas: product quality, customer satisfaction, employee and leadership development, operational optimization, financial viability, infrastructure strategy and performance, enterprise resiliency and community sustainability.

The WRF also recently received national recognition as a Utility of the Future Today (UotFT) from the Water Environment Federation (WEF), National Association of Clean Water Agencies (NACWA), Water Research Foundation and WateReuse Association. The program recognizes water resource recovery facilities for transformational work in community engagement, watershed stewardship, and recovery of resources such as water, energy, and nutrients. HBPW was recognized for its continued efforts to increase beneficial reuse of solids generated as part of the wastewater treatment process and the anaerobic digester will be a key factor in these efforts in future years.

The PUMP and UotFT Awards are the result of the HBPW’s commitment to sustainability, which is further being advanced by the anaerobic digester and the ENVISION process. “We are confident that ENVISION guides us in the right direction,” remarked Dave Koster, General Manger. ENVISION is more than an award, it is a framework for ensuring that every stage of the infrastructure project considers sustainable practices. ENVISION provides independent validation that Holland Board of Public Works makes choices that will enrich our community well into the future.

Sanitary Sewer Renewal in Areas Affected by High Lake Levels

Holland Board of Public Works (HBPW) identified that high groundwater levels threatened the reliability of the wastewater collection mains in its service territory along Lake Macatawa. Holland reached record high lake levels during the summer of 2019. The lake levels remained elevated and continued to rise through 2020. Combined with higher levels of precipitation, the lakeshore experienced very high groundwater levels.

Excessive groundwater was found to be infiltrating into the sewer system along the lakeshore at a higher rate than normal, posing the potential for backups in sewer mains in the area. The most common source of this groundwater infiltration is older sewer mains and private sewer services that may have cracks or broken pipe joints that allow groundwater to flow into the sewer. Another common source is sump pumps that are illegally connected to the sewer system. To address potential issues with the HBPW owned and maintained sewer mains, all older clay sewers along the lakeshore were targeted for rehabilitation using non-intrusive sewer lining technology.

HBPW uses cured-in-place-pipe (CIPP) lining to renew sewers and extend their useful life. This technology results in a new pipe inside of the original sewer that is fully structural and eliminates defects that allow the infiltration of groundwater. 7,500 feet of clay sewers along the south side of Lake Macatawa received CIPP lining in 2020.

Sewer lining is cost-effective and less disruptive to the community than sewer replacement. “Our contractors can install 700 feet of sewer lining in a day with minimal disruptions,” explained Pieter Beyer, Superintendent of Water and Wastewater Services. The lining is made of flexible material coated with resin. “Think of it as a glue-impregnated sock.” The lining is inserted into the existing sewer main and inflated until it covers the internal cavity of the pipe. The resin is then cured using steam and the liner hardens into a new plastic pipe without ever tearing up the roads. Sewer lining has a significantly lower cost than replacement. “The comparison is approximately $40/foot to line a typical residential sewer, whereas traditional excavated replacement can cost in excess of $300/foot.” The result is a completely renewed sewer with a lifespan of approximately 75 years.

In addition to the sewer lining project, Holland Board of Public Works did a full inspection of the remaining newer wastewater sewers in the south shore area to identify other potential issues that should be mitigated. Using a robotic CCTV sewer inspection camera, a total of 32,250 feet of sewer was inspected for structural concerns, maintenance needs, and potential illicit sump pump connections. The robotic cameras are designed to drive through sewer pipes to help identify issues like broken sewer mains or services, clogs, tree root growth, and improper discharges to the sewer. “The camera helps us find risks before they cause big problems. A common problem these days for all wastewater utilities are clogs caused by so called “flushable” wipes. While the wipes may be marketed as “flushable”, that only means that they can get flushed by a toilet. Once they are past the toilet and in the sewer system most do not break down in the same way that toilet paper does, and instead can get tangled with each other and stuck in the sewers, which can lead to very serious backups,” said Beyer.

Holland Board of Public Works takes a proactive approach to maintaining the sewer mains. Dedicated to reliability, HBPW puts forth great effort to curtail problems that might otherwise originate in the public sewer main.