Advancing the Way We Clean the Region’s Wastewater

By upgrading existing treatment infrastructure instead of expanding, the Holland Area Water Reclamation Facility (WRF) is saving money while ensuring effective treatment for years to come. Over the past 15 years, HBPW has studied carefully the potential for expanding the WRF to meet growing community wastewater output. However, the 2008 economic recession combined with trends in water conservation and sewer system improvements led to a level-off in average daily flow, which left us wondering if expansion was the right choice.

The WRF treats sewage from Holland and several surrounding townships at our River Ave./3rd St. location, which actually consists of two interconnected plants – East and West. Some of the wastewater we treat is residential, but a large portion comes from local industry and large food processors. While the overall daily flow from the community hasn’t increased much in 15 years, growth in the industrial segment has increased the concentration and strength of the waste significantly.

*Biochemical Oxygen Demand is a measure of the amount of oxygen necessary to feed the microorganisms that break down organic contaminants in the water. *Total Suspended Solids are the solid materials both organic, and inorganic, that are suspended in the water.Most of the existing equipment on our East Plant is greater than 35 years old and isn’t as efficient at handling the highly concentrated waste. With maintenance costs for the older equipment on the rise, we turned to optimization strategies and replacement equipment to increase efficiency and ensure capacity for future growth. The solution we settled on involves two big upgrades:

Biosolids Handling Upgrades:

Biosolids Handling Upgrades:

A nearly total replacement of the WRF’s biosolids handling processes, which includes major equipment investments in two Gravity Belt Thickeners (GBTs) and four dewatering screw presses. The GBTs and screw presses remove excess water from solids extracted from the clarifiers on both East and West Plants and prepare the solids for ultimate disposal. We also stabilize thickened solids with lime before they’re hauled to local farms to be subsurface injected as a fertilizer and soil conditioner. Dewatered solids are disposed at a local landfill and can help with methane gas production (which may be used for power generation at the landfill). The new processes and equipment will enable our facility to handle more waste and increase the corresponding energy efficiency.

Secondary Treatment Optimization:

Secondary Treatment Optimization:

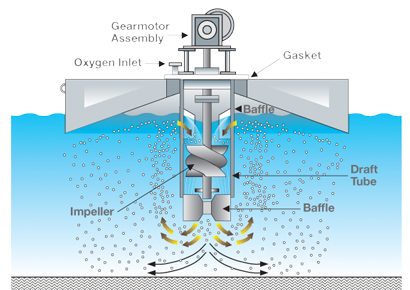

An upgrade of our secondary treatment process to add pure oxygen in the aeration process. Wastewater treatment utilizes microorganisms that feed on harmful organic matter in the water, and these good bacteria need a lot of oxygen to work effectively. Our East Plant currently mixes in air to our aeration basins to help feed that demand. Our upgraded system will instead use pure oxygen for this purpose. This modification enables us to treat a more concentrated waste stream in the same tanks, thereby eliminating the need for a costly expansion of our existing footprint.

Since the Holland Area Water Reclamation Facility service area extends far beyond the city into several townships of Ottawa and Allegan Counties, we worked with Ottawa County to raise the $24 million needed through bonds. Ottawa County has a AAA bond rating that offers some of the lowest interest rates on the market, which helped us to sell $19 million in municipal bonds to fund the project. While much of the major construction will be completed in 2015, the plant is expected to be fully operational with the new equipment in August, 2016.